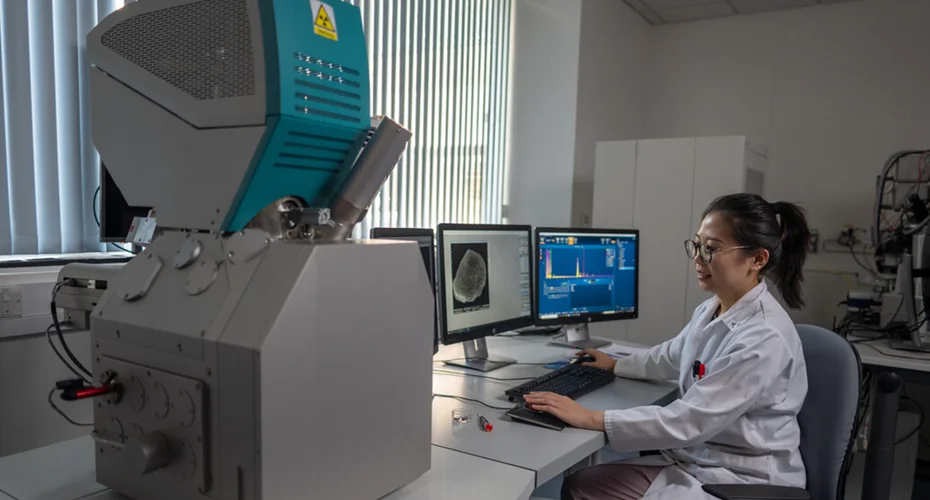

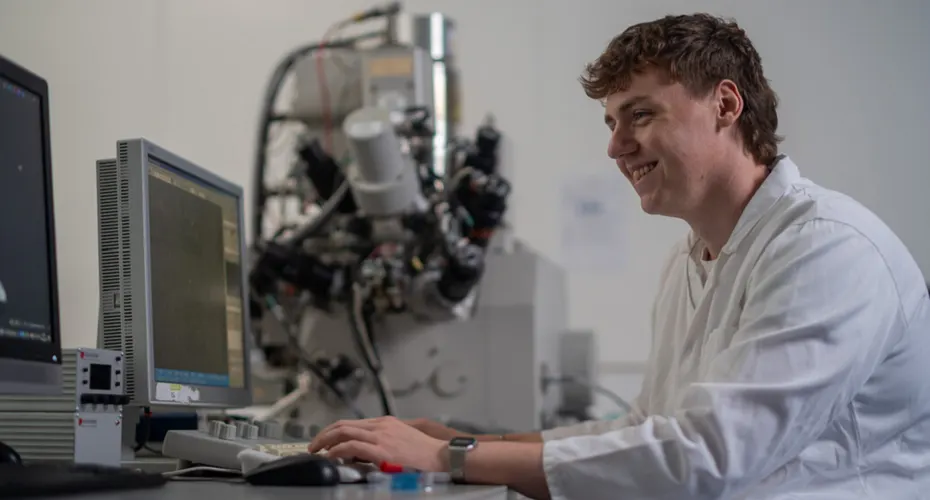

Imaging Suite

The Imaging Suite offers a full consultation service to internal, external and industrial clients in the field of materials characterisation for experimental applications at micro and nano scales. It also supports research and teaching in the College of Engineering, Maths and Physical Sciences.

Our services

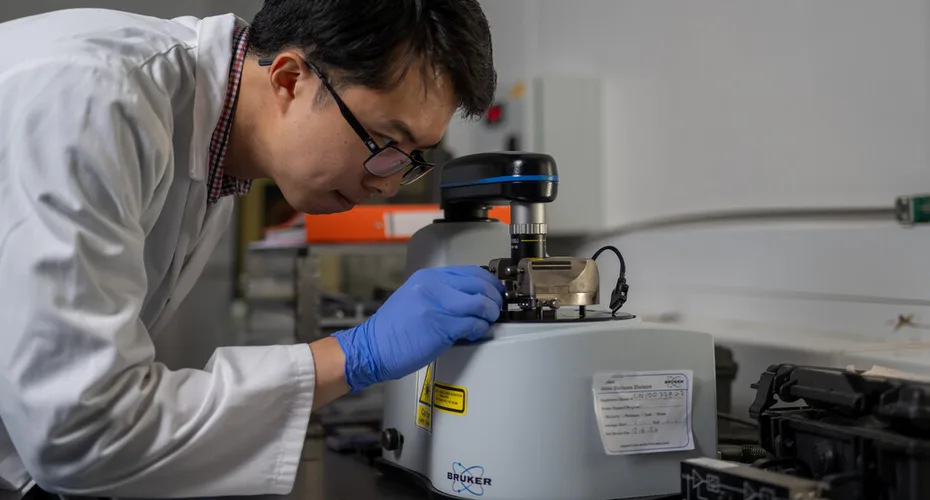

- Access to our facilities comes with the associated expert and technical assistance to support routine work on a timed basis or contribute to a significant programme of research and testing.

- We will work closely with you throughout the process, from the initial project concept to final delivery, to deliver the results to your specification.

- We are happy to prepare the samples and provide training for customers.

- In offering these analytical techniques, together with additional expert services, we aim to be a powerful problem solver for the challenges you are seeking to overcome.

To discuss your project, please contact Dr Hong Chang, Imaging Suite Manager.