Thermodynamics and fluid dynamics

Thermodynamics laboratory

Our thermodynamics laboratory has several pieces of equipment that are used to understand the relationship between temperature and energy. Understanding thermodynamics is particularly important to mechanical engineering and civil engineering.

| Engine test bed |

Understanding fuel consumption is important to mechanical engineering. This facility is used in teaching and demonstrates aspects of a combustion engine. By analysing various parameters such as fuel consumption, air box differential exhaust temperature, etc, the user can evaluate performance in relation to a range of torque loadings on the engine. This is like simulating the engine pulling a car up the hill at different slopes. We are also able to measure the torque placed onto the engine and temperature of the exhaust vs room temperature. |

| Combined convection and radiation system | This facility is designed to demonstrate how heat transfers from a solid surface to its surroundings. It has a radiating heat source which can demonstrate convection mechanisms by use of regulation incorporated fan. |

| Expansion processes of a perfect gas | This apparatus shows the behaviour and expansion processes of a perfect gas, and allows you to understand the relationship between pressure volume and temperature. Each pressurised vacuum vessel has a temperature probe that is linked to a reader, allowing its user to make accurate decisions. |

| Armfield heat exchange unit |

The Armfield heat exchange unit is part of a range of heat exchanger units for studying the practical implications of different types of exchanger. Heat exchangers are devices that transfer heat from one medium to another. These devices are commonly used in refrigeration, air conditioning, power stations and combustion engines. The set piece modules are interchangeable on the unit and are used for practical evaluation and our students also design their own heat exchanger and apply it to this theoretical facility to examine and measure the effectiveness of their design. |

Aerodynamics laboratory

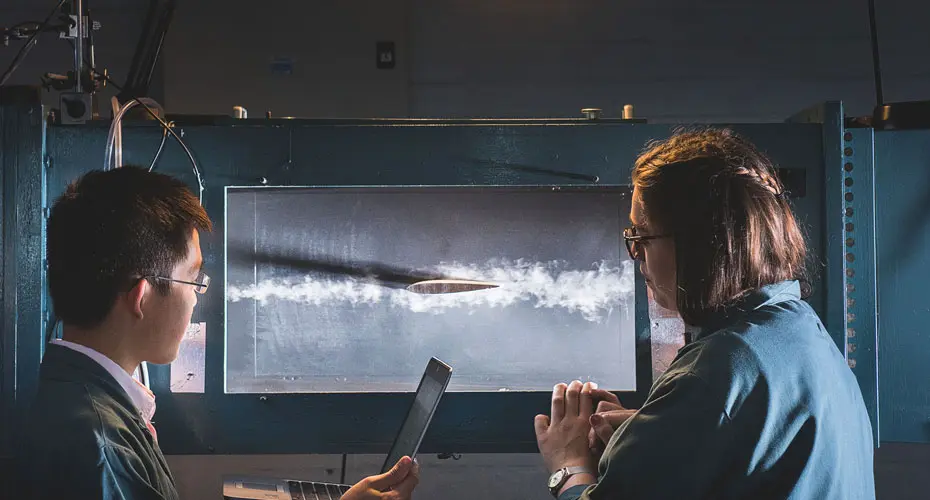

This laboratory has a series of wind tunnels that can be used to examine the properties and behaviour of aerodynamics. Whilst each machine shares the same purpose, they all range in sizes and air flow rate. Our students create models and place them within the tunnels to perform experiments to understand behaviour such as lift and drag.

We have a smoke generator to allow the viewer to see the dynamic interaction between model and air flow. There is also a strobe light that can be used to calculate the speed of rotation if the model has rotating parts such as a turbine. Pitot tubes can measure the air pressure on the side of the models, which allows the user to monitor and record the air pressure and other aerodynamic properties.

Fluid dynamics laboratory

This laboratory has a range of instruments that allow the theories of fluid dynamics to be put into practice. Fluid dynamics has a wide range of applications and the laboratory equipment can assist and model real problem solving with structures and environments.

| Large Armfield flume | A self-contained glass sided flume with a working length of 10m and working cross-section of 600mm wide by 450mm deep. The facility provides a versatile solution to model and simulate the impact of fluid dynamics. |

| Visualisation tank | The visualisation tank has a clear base, allowing its user to clearly see how fluids flow over a certain substance, for example sand. |

| Hydraulics bench | This facility provides a variable controlled recirculation of water in a standalone unit. An internal flowmeter can measure the outlet flow from top open channel or associated attachments. |

| Flowmeter demonstration rig | This facility introduces its user to types of flow meters (instruments used to measure linear, nonlinear, volumetric and mass flow rate of fluids or gasses. An application of this facility is for measuring volumetric flow rate to understand how bends in pipework may affect the flow meter and ultimately cause pressure in unwanted areas. The rig introduces the concepts of three different types of flowmeter and facilitates direct comparison. |

| Sedimentation tank | This facility is a scaled down version of the real-world sedimentation tank, used in all modern water systems to treat water. It examines how particles separate depending on various parameters such as input water volume and flow, concentration of contaminant and physical position with separation weir. From this, the user can understand the treatment process from start to finish. |